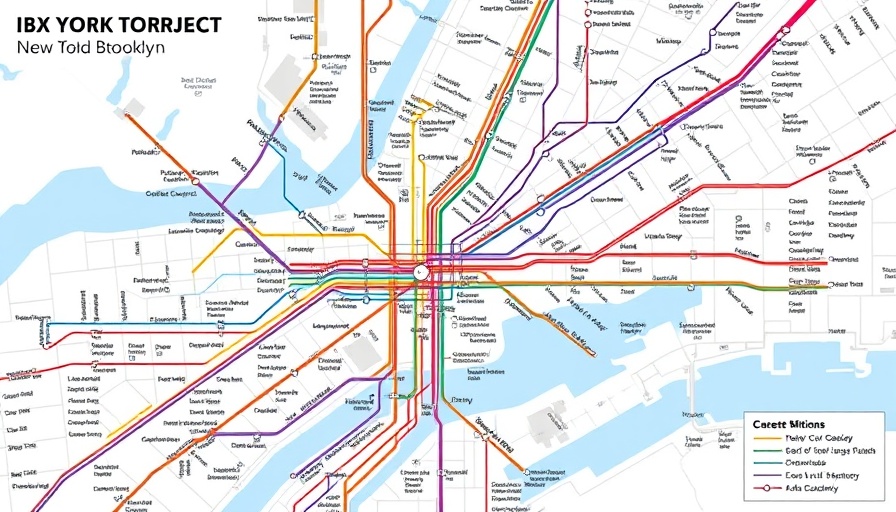

Transforming Public Transit: The IBX Light Rail Project

New York City is taking a significant leap in public transit innovation with the approval of the Interborough Express (IBX) light rail line set to connect Queens and Brooklyn more efficiently. This ambitious project, which is expected to cost approximately $5.5 billion, will utilize existing freight rail infrastructure to enhance connectivity for nearly 1.15 million residents across both boroughs.

Understanding the Impact: A Game Changer for Commute

The IBX line aims to serve around 200,000 passengers daily by repurposing the underused Bay Ridge Branch and Fremont Secondary lines. As the Metropolitan Transportation Authority (MTA) gears up for construction, the focus remains on cutting down travel times significantly. The anticipated travel duration is around 40 minutes, which is expected to lessen congestion and promote economic activity in surrounding neighborhoods.

Community Benefits: Accessibility and Economic Growth

According to MTA officials, this rail connection will not only facilitate quicker travel across the two boroughs but also offer vital access to critical services and job opportunities for nearly 900,000 residents. With 19 planned stops, commuters will enjoy better access to the Brooklyn waterfront, aligning with urban development goals aimed at enhancing local economies.

Challenges Ahead: Navigating Future Transit Trends

Even as excitement builds for the IBX, challenges remain. Some residents are concerned about the potential impacts of construction on their neighborhoods. Additionally, the long-term sustainability of such projects hinges on reliable funding and robust community engagement throughout the development phase. As building companies within this sector watch closely, there’s an important opportunity to innovate and contribute solutions that meet both construction demands and community needs.

As Building Professionals, Stay Informed

For companies invested in the construction and transportation sectors, understanding and staying updated on projects like the IBX is crucial. As New York City continues to evolve its infrastructure, an awareness of emerging trends and developments can inform strategies that enhance business opportunities. Companies should prepare to showcase their equipment and expertise, aligning with the rapidly changing landscape of regional transit.

Add Row

Add Row  Add

Add

Write A Comment